[Exhibition Report] Exhibited at Automotive Engineering Exposition 2025 YOKOHAMA

We exhibited at the “Automotive Engineering Exposition 2025 YOKOHAMA,” held from Wednesday, May 21 to Friday, May 23, 2025, at Pacifico Yokohama.

Over the three days, the exhibition welcomed more than 79,000 visitors, and many customers visited our booth as well.

We would like to express our sincere gratitude to everyone who stopped by.

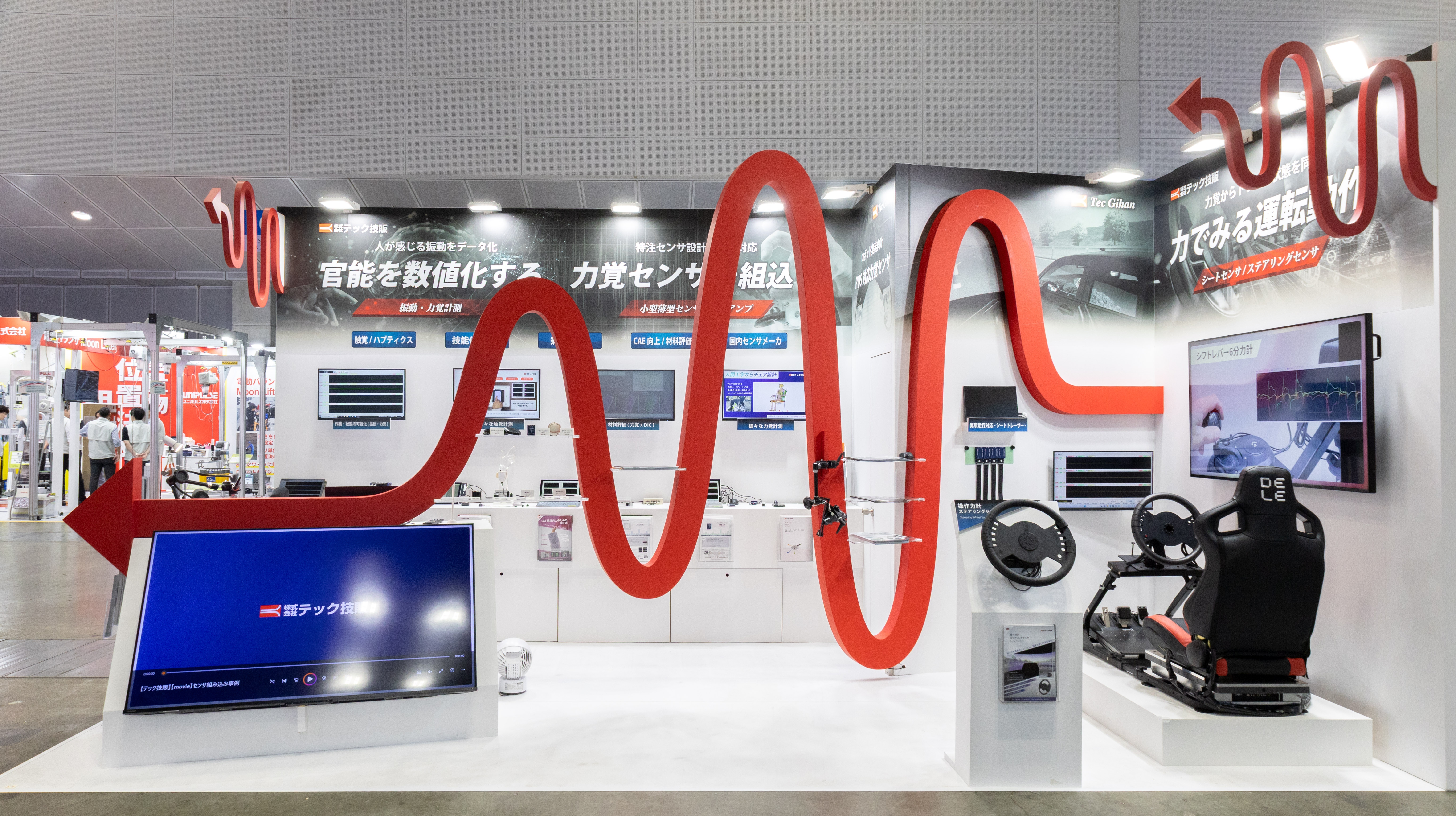

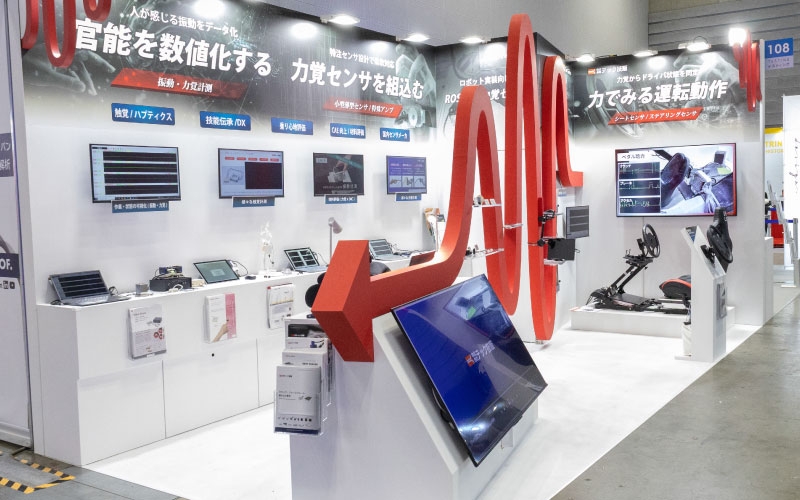

Booth Concept

As a specialist manufacturer of force sensors, Tec Gihan has developed its booth around the theme of “visualizing force vectors.”

This year, we completely redesigned our booth, moving away from the conventional “arrow-shaped” design and introducing a new waveform-inspired vector concept to create a more impactful and immersive space.

[New Product] “Visualizing Driving Operation Through Force” – Operation Force Meter / Steering Sensor

Following last year’s theme, “Visualizing Driving Operation Through Force,” we presented live demonstrations in which force sensors and force plates were integrated into car seats, shift levers, accelerator pedals, and brake pedals to visualize changes in force during driving in real time.

In particular, this year we newly introduced an “Operation Force Meter (Steering Sensor),” which displays subtle changes in steering force in real time during steering operations.

From how force is applied to the steering wheel while driving, applications are expected in understanding driver psychology, evaluating vehicle performance, and assessing ADAS interfaces.

Representatives from S&VL Corporation, a user of the steering sensor, also joined us at the booth and explained how the sensor is actually utilized in driving simulators.

・ Sensors can be customized in size and rated capacity according to the application.

・ Ideal for embedding into products such as seats. Please feel free to contact us for consultation.

The Potential of Force Measurement and Haptic Sensing

In this section, we presented various live demonstrations using force sensors.

Force sensors are not limited to measuring loads alone; they can also be applied as haptics (tactile) sensors and used to quantify friction, softness, and material properties.

In the field of sensory evaluation, incorporating objective, quantitative assessments in addition to conventional subjective evaluations contributes to more advanced product development and quality control.

Human tactile perception consists of various elements, and we approach it quantitatively through force sensation, friction, and vibration.

[Advance Preview] VibraScope

The new device “VibraScope” simultaneously measures the following three elements generated during work.

It also proposes a solution for skill transfer and work DX—one of the challenges facing Japanese manufacturing—by visualizing craftsmen’s work through “force” and “vibration.”

・ Tactile vibration transmitted to the worker’s hand

・ Vibration of the target object itself

・ Component forces of the load applied during work

At the exhibition, we conducted a live demonstration based on a simple task: “rubbing a spoon on sandpaper.”

By comparing different grit sizes, changes in force and vibration were visualized in real time.

By converting tactile differences such as “roughness” and “resistance” felt by hand into numerical values and waveforms, VibraScope enables data sensing for quantitative tactile evaluation, quality control, and skill transfer.

Being able to quantitatively grasp when, in which direction, and how much force is applied, as well as what kind of vibration is felt and the vibration patterns of the target object, is expected to be applied to training, process improvement, and quality enhancement.

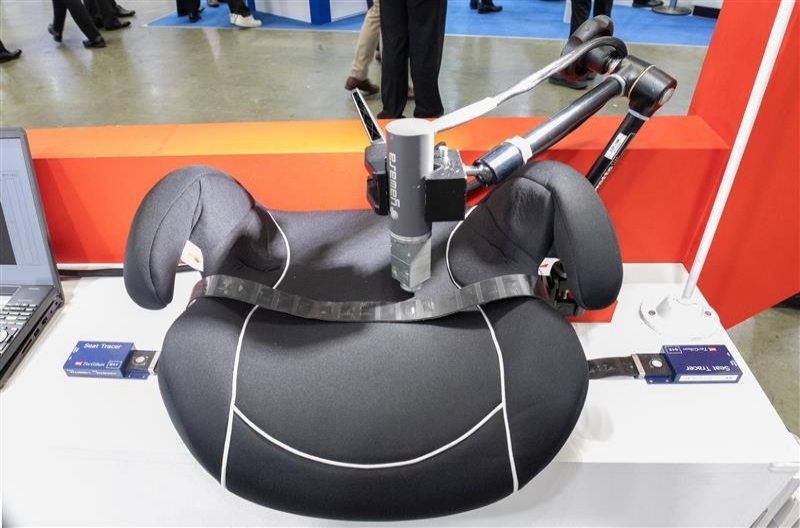

YAWASA

YAWASA is an indentation testing device that quantifies the softness of materials for physical property evaluation.

As ride comfort continues to attract attention, this theme has been adopted in seat development.

This time, we measured the softness of urethane using a junior seat.

VibraScope

YAWASA

[Experimental Proposal] Approaches to Soft Materials That Are Difficult for CAE

In recent years, CAE-based design has become mainstream; however, there are still targets such as soft materials and layered components of dissimilar materials that are difficult to analyze numerically.

Therefore, we proposed acquiring experimental data through real experiments by combining:

“Component force measurement” × “Image measurement (DIC: strain, displacement, vibration).”

By measuring dynamic loads sensed by force sensors and reflecting them in CAE, more accurate simulations can be expected.

Dynamics Measurement Mode

Measuring the three-dimensional shape of seats during actual vehicle driving has traditionally been difficult due to the influence of acceleration applied to the entire vehicle, which disrupts sensing data.

By revising our algorithms, we developed a mode that supports vibrations and motion during real vehicle driving.

*From left: HapLog, DIC, Real-vehicle driving–compatible Seat Tracer

[Advance Notice] ROS-Compatible Sensors (Coming Soon)

Tec Gihan is currently working on compatibility with “ROS (Robot Operating System),” which is widely used as a standard in robotics development.

Going forward, our various sensors will support control and data acquisition via ROS, further expanding applications in robotics and automation solutions.

Conclusion

Through the “Automotive Engineering Exposition 2025,” we felt a strong sense that sensing technologies are creating new connections between people and technology.

Tec Gihan will continue to propose solutions that contribute to problem-solving by visualizing “force” and “vibration.”

If you are interested in our products or demonstrations, please feel free to contact us.

Contact us here

contact@tecgihan.co.jp