[Exhibition Report] Exhibited at Manufacturing World Japan 2024 – Measurement, Inspection & Sensor Expo

From June 19 to June 22, 2024, we exhibited at the “Manufacturing World Tokyo – Measurement, Inspection & Sensor Expo,” held at Tokyo Big Sight.

We were delighted to welcome many visitors to our booth, and thanks to your support, the exhibition concluded successfully.

We sincerely appreciate everyone who stopped by.

Despite the unfavorable weather on the final day, our booth remained lively with a steady stream of visitors from start to finish.

Booth Details

This year’s booth design continued the motif introduced at last month’s “Automotive Engineering Exposition,” incorporating three colored arrows representing force vectors.

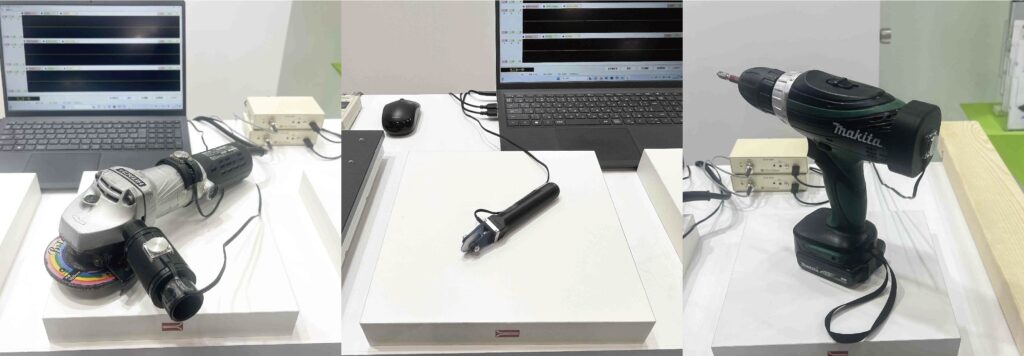

Force Sensing Demonstration Corner

In line with the theme of Manufacturing World, we showcased real-life installation examples of force sensors.

This demonstration featured compact 3-axis force sensors embedded in a **glass cutter wheel**, **electric screwdriver**, and **sander**, visualizing how force is applied during use.

Glass Cutter Wheel: Measures cutting resistance in the forward direction and detects lateral deviation to determine blade replacement timing.

Electric Screwdriver: Ensures that the tool is operated with sufficient vertical pressing force to prevent stripping screw heads.

Sander: Sensors embedded in two grip points measure the balance of pressing force applied by the left and right hands.

Visitors could observe their applied forces in real time, visualizing both direction and magnitude.

Force & Tactile Measurement Corner

As with last month’s exhibition, this corner focused on demonstrations using force sensors.

Force sensors are not limited to measuring load—they can also be utilized as haptic sensors in tactile applications when paired with ultra-high-sensitivity models.

Our product lineup includes sensors for measuring friction, quantifying softness, and evaluating material properties.

In addition to traditional sensory evaluations, why not incorporate objective numerical data to enhance assessment accuracy?

Skill transfer has become a major challenge in Japanese industry, and we propose analyzing craftsmanship through force and vibration.

Traditionally, artisans have relied heavily on intuition and experience, making training inefficient and difficult to formalize.

By using force sensors, it becomes possible to numerically capture when, in which direction, and how much force is applied—shifting training from subjective, sensory instruction to objective, data-driven guidance.

Vibration sensors can also quantify vibration transmitted to workers during tasks, supporting OK/NG judgment based on shared, measurable criteria.

This corner also drew strong interest from many visitors.

Catalogs from the exhibition are now available for download

-

Skill Transfer Through Force Measurement – Vol.2

Skill Transfer Through Force Measurement – Vol.2Download

Skill Transfer Through Force Measurement – Vol.2

Skill Transfer Through Force Measurement – Vol.2Download

-

Sensor FP – Embedded Installation Examples

Sensor FP – Embedded Installation ExamplesDownload

Sensor FP – Embedded Installation Examples

Sensor FP – Embedded Installation ExamplesDownload

Next Exhibition

We will be exhibiting at the “Automotive Engineering Exposition 2024 NAGOYA” in July.

We look forward to seeing many of you there.