Skills Transfer/DX/Labor-saving

力でみる技能伝承 目に見えない「力」に解決のヒントあり

For generations, many skilled manufacturing processes have relied on the intuition and tactile sense of experienced craftsmen — their “feel” and “knack” (in Japanese, “kan” and “kotsu”).

However, these valuable skills are often difficult to pass down to successors or translate into automated production systems.

At Tech Gihan, we focus on visualizing and quantifying these invisible skills — sensing how force is applied during manual work, converting that information into data, and using it for training, automation, and process optimization.

-

Quantifying Sensation and Technique

By measuring and analyzing the force usage in traditional manual processes — such as polishing, plastering, scraping, lathe machining, or tapping — we can extract valuable data that was once only accessible through experience.This quantification enables a wide range of applications: Accelerated training and skill transfer by clarifying how skilled workers apply force. Automation and robotics development, using big data to understand the patterns and trends behind expert craftsmanship. Through this approach, we aim to bridge the gap between human intuition and digital precision.

-

Real-Time Force Feedback

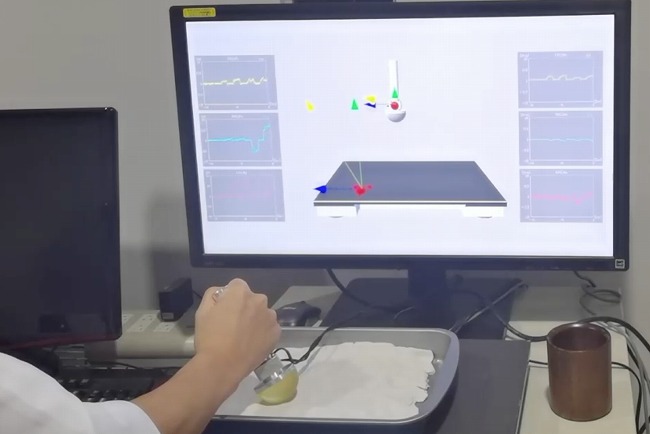

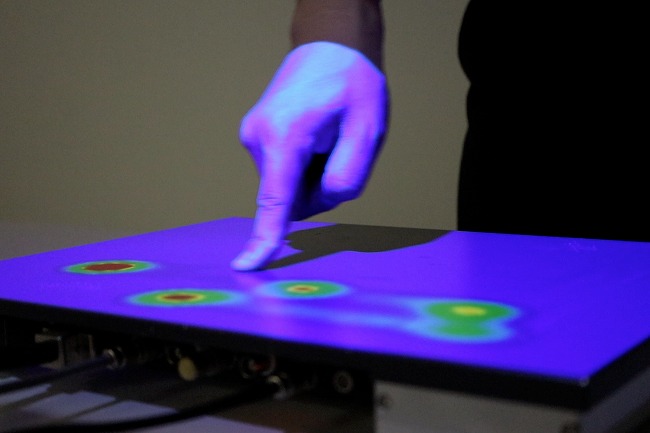

One of the key features of Tech Gihan’s system is real-time force feedback. By sensing force during operation and monitoring it in real time, workers can perform tasks with greater consistency and control. Different visualization methods can be applied: Displaying force magnitude and direction as vectors. Using projection mapping to show heat maps of force intensity directly on the work surface. Converting force data into sound for auditory feedback in noisy or high-speed environments. We tailor each feedback method to suit the specific needs of the worksite.

Expressing the strength and direction of force with a "vector"

Expressing the strength and direction of force with a "vector"

Projecting force heat mapping onto the work object

Projecting force heat mapping onto the work object

-

Visualizing Various Craft Processes

By embedding miniature multi-axis force sensors into tools, we can visualize and record the physical forces used in a wide range of operations — from sawing and plastering to calligraphy. Even delicate motions, such as the subtle brush pressure in Japanese calligraphy, can be captured using our Tactile Force Plate, which detects minute changes in applied force. This enables not only large-scale industrial measurement but also high-sensitivity sensing of fine, artistic movements.

-

Vibration — Another Key to Human Sensation

In many manufacturing and finishing processes, workers rely on vibration feedback to judge quality. For example, in grinding or polishing, subtle vibrations transmitted through the hand convey important information about surface finish and tool condition. Until recently, such sensations were expressed only through onomatopoeia or subjective evaluation, making quantitative analysis difficult. TecGihan’s “Finger Recorder” system enables users to capture, share, and quantify vibration data, allowing what was once a “feel-based” judgment to be transformed into objective, measurable information. Our systems combine vibration measurement with force sensing and inertial data acquisition (acceleration and gyro), enabling synchronized multi-modal analysis. In the pursuit of automation of sensory-based work, the first crucial step is quantifying the sense itself — turning human perception into data.

-

- Force Sensor / Amplifier / Interface

- Basic force measuring instruments including one of the world's smallest class of 3-axis force sensors.

-

- Force Plate

- 6 force components measuring platform that can be used for the measurement of walking, running or standing-up motion.

-

- Tactile & Texture Measurement

- Tactile and texture evaluations using our force or vibration measuring instruments.