Material Evaluation

-

Material Properties and Evaluation

The world is filled with materials of diverse functions — some absorb impact or vibration, others efficiently conduct heat or prevent slippage. At TecGihan, we quantify and analyze these material characteristics through the precise measurement of load, friction, vibration, and other physical parameters.

-

Measuring Soft Materials

One of the most common methods for evaluating materials is the tensile and indentation test. However, conventional testing machines are not suitable for soft materials such as jelly or pudding, where delicate force control and sensitivity are required. To address this challenge, TecGihan has developed and commercialized the YAWASA Soft Material Indentation Tester — a precision testing device designed specifically for soft materials. By analyzing the force–displacement (F–S) curve, users can derive parameters such as elastic modulus, viscosity, and Young’s modulus with high accuracy.

-

Friction Force Evaluation

In many products and tools used by people, contact between human skin and materials — or between different materials — is inevitable. To develop optimal materials, understanding how much frictional force is generated under specific conditions is essential. Using force plates and multi-axis force sensors, TecGihan can accurately measure shear and normal forces to calculate the coefficient of friction. Applications include: Textile evaluation — fixing fabric samples onto a Tactile Force Plate, then sliding a finger across the surface to measure friction and tactile feel. Tire testing — running tires on a large-scale force plate to analyze traction and grip performance. By combining vibration sensors, it is also possible to simultaneously measure friction and vibration, providing a more comprehensive understanding of material behavior.

-

Measuring Complex Materials Beyond CAE Simulation

Force × DIC (Image-Based Measurement)With the advancement of CAE, development is now often carried out through simulations without using actual objects in order to speed up development. However, CAE cannot simulate all phenomena, and there are situations where actual measurements are needed to understand what is actually happening. Examples include structures where soft materials, like human skin, are layered together, or new materials with complex shapes. For difficult objects, CAE can not only measure force, but also simultaneously measure displacement, stress, and vibration components, thereby clarifying the phenomena and leading to improvements in CAE. Image measurement using DIC (Digital Image Correlation) allows for non-contact measurement of strain and stress on objects coated with a random dot pattern.

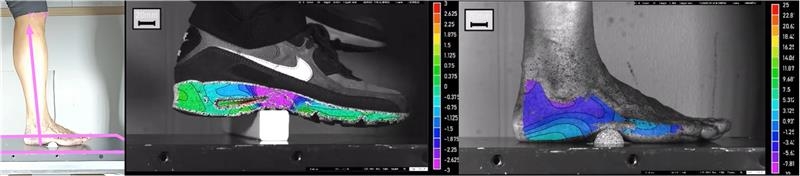

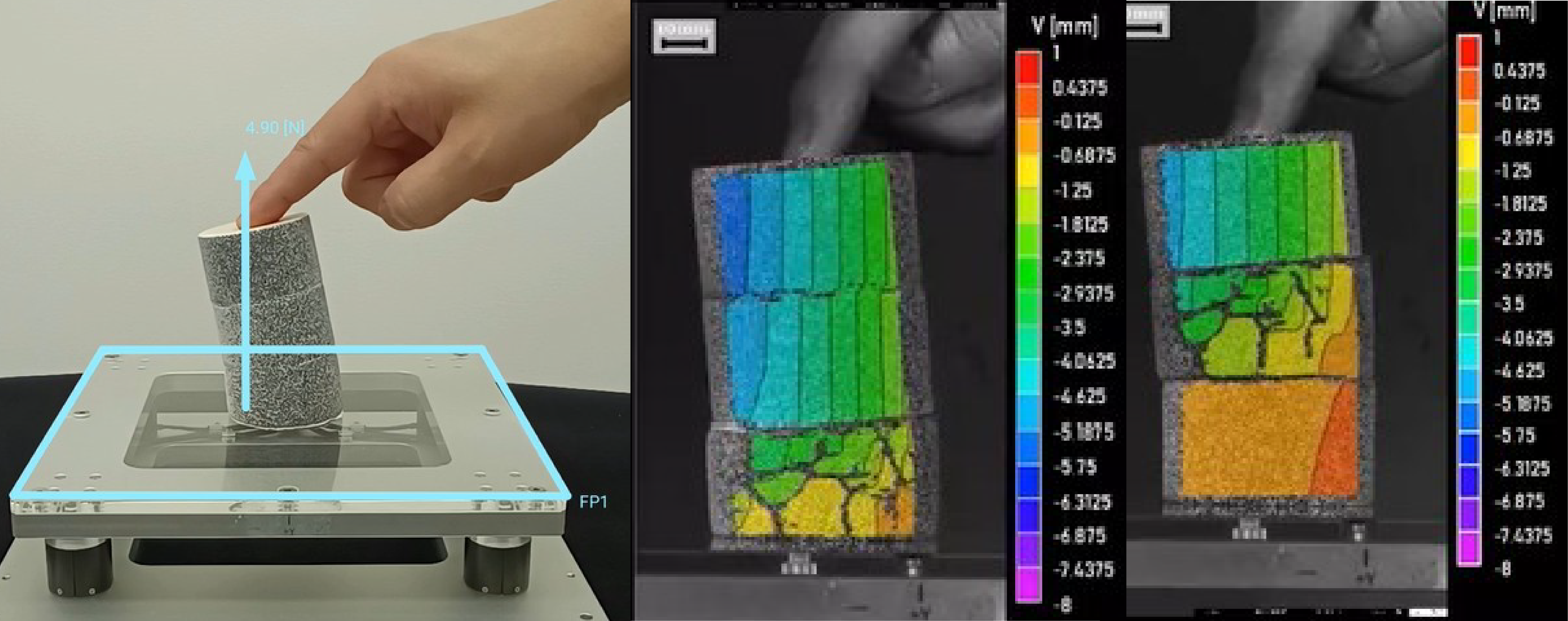

Measuring walking and running using force plates is often used to evaluate gait. In this study, a random dot pattern was applied to the sole of a shoe to evaluate sports equipment, and strain and stress were measured using DIC. The deformation characteristics of human skin (in this case, the foot) were also measured. Dynamically measure the strain when different soft materials are layered. How deformation is transmitted can be seen by changing the layering order.

Dynamically measure the strain when different soft materials are layered. How deformation is transmitted can be seen by changing the layering order.

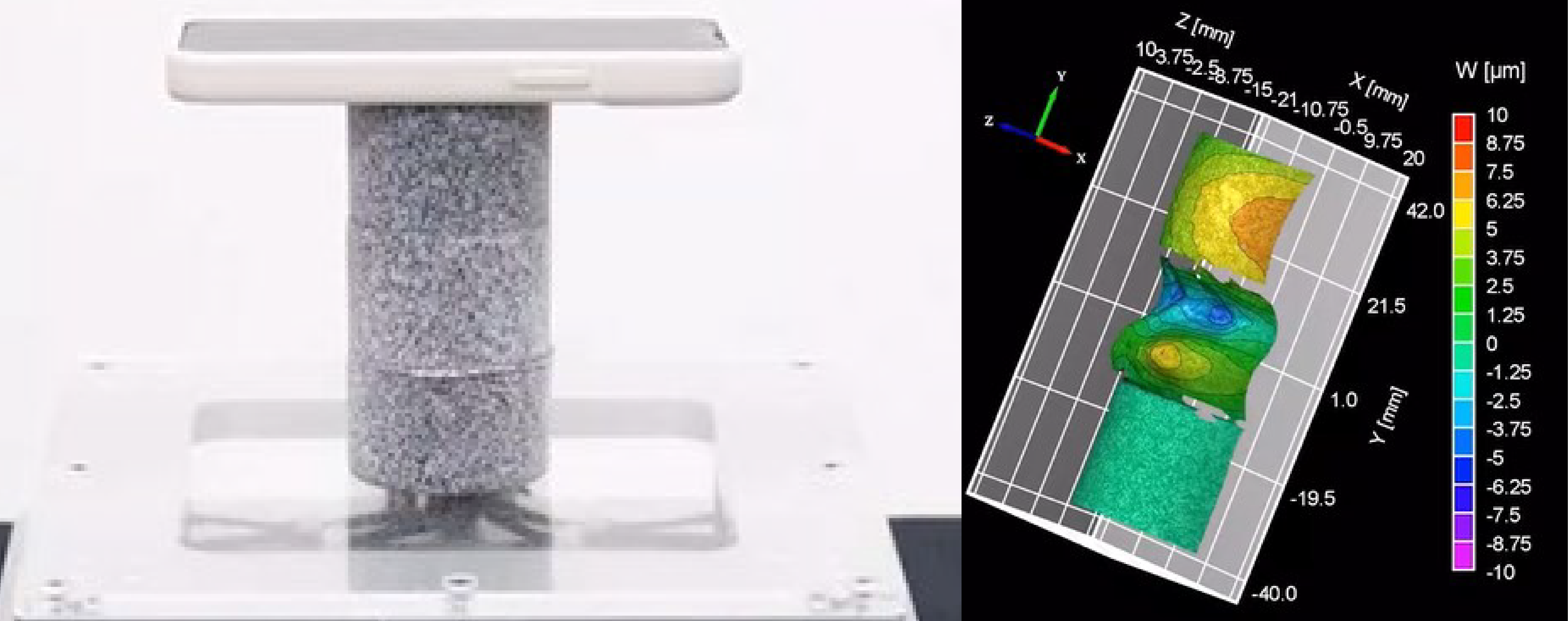

There is also an approach that applies DIC measurements to analyze vibration components even in objects where no changes in deformation or stress are observed. The above example measures how the vibration of a smartphone is transmitted to soft materials and where the resonance point is.

There is also an approach that applies DIC measurements to analyze vibration components even in objects where no changes in deformation or stress are observed. The above example measures how the vibration of a smartphone is transmitted to soft materials and where the resonance point is.

-

- Force Sensor / Amplifier / Interface

- Basic force measuring instruments including one of the world's smallest class of 3-axis force sensors.

-

- Force Plate

- 6 force components measuring platform that can be used for the measurement of walking, running or standing-up motion.

-

- Tactile & Texture Measurement

- Tactile and texture evaluations using our force or vibration measuring instruments.